The Art of Hand Crafted Print

While we are sadly unable to visit India, we wanted to take you on a journey behind the scenes to see how we develop our hand-screen prints with our wonderful artisan partners

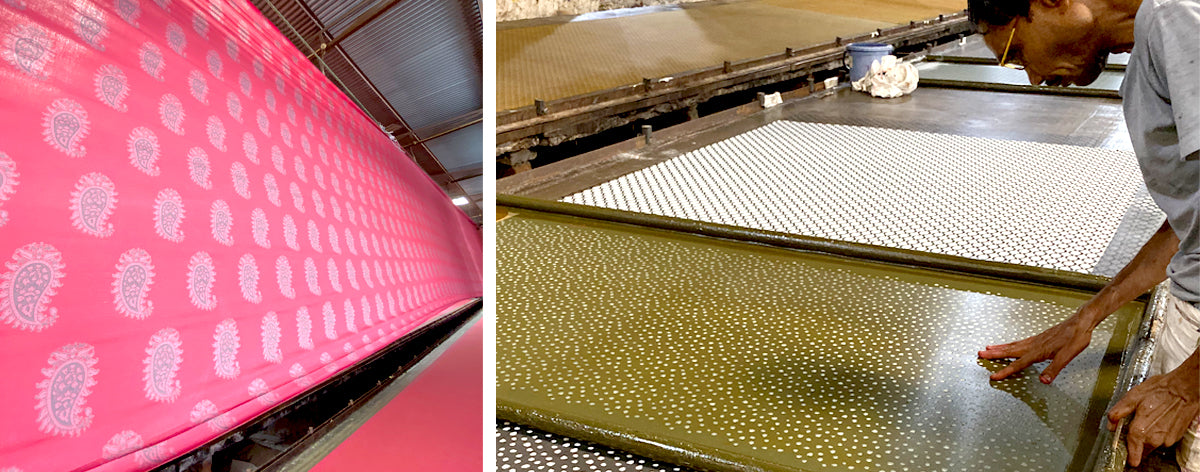

On our last trip to India in October we drove about an hour outside of Jaipur to spend the day working with the highly skilled artisans at our hand-screen printing unit. Based in a rural village and surrounded by lengths of hanging fabric drying in the warmth of the sun, the artisans bring our designs to life through truly skilled craftsmanship, working their magic to develop designs and create our newest collections. The unit specialises solely in screen printing, creating fabrics for companies all across the world and throughout India. We feel so privileged to work with such a beautiful heritage craft and can't wait to return!

The Screen Print Process

To start the process a mesh screen is stretched over a wooden or aluminium frame and then covered with a light-reactive emulsion. The design is applied to an acetate sheet which is then laid over the emulsion and exposed to a bright light for a set time - any areas of the screen not covered by the design will turn hard. The unhardened emulsion is then carefully rinsed away leaving a clear imprint of the design on the screen for the ink to pass through. Each colour for the design requires a screen of its own. Layers of colour are built up carefully lining-up each layer to make the beautiful finished piece.

A stencil is used for each layer of colour for the design and great skill and experience is required, lining up designs with such speed and precision.

Colour is poured on to the screen at one end and a squeegee is passed from one side to the other and back again to press the colour through the stencil. This is repeated down the full length of the cloth, lining each screen side by side. These lengths are dried and then new colours are layered, repeating the process over and over to complete the design.

One of our favourite parts of hand screen is the unique nature to each meter, no layers are 'perfectly' aligned and that's where the beauty lies: in the perfectly imperfect result.

The screens developed in October as shown in the images from above were used for the Sophie Spot styles as pictured above.

We hope you enjoyed our photo diary!

Sending love to you all from the whole team at East x

3 comments

So glad to read you are supporting Indian craftsmen. Where are your garments assembled? I’m trying my hardest to avoid anything made in China.

Denise Bennett

Love the pink fabric in your post. Similar to a wonderful turquoise print you did a few years ago. Can we have dresses in both of these please?

Jayne

Visited Jaipur last month and saw (and had a go at) hand blocking. Not easy!

Sue Thackray

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.